HAZOP

HAZOP / HAZID / LOPA

HAZOPs have been a subject of great interest to me ever since I started participating in them 12 years ago as a process engineer. I now wish to go further and use my knowledge and experience to present and train engineers and conduct courses related to HAZOPs. I have myself attended the course ‘HAZOP study for team leaders’ and found it to be extremely useful. I believe I can add value to the course by emphasizing on the software applications (like PHA works) and demonstrate that the HAZOP studies can be carried out more efficiently and shorter periods of time without compromising on the quality. As one is aware HAZOPs tend to be very labour intensive and require large manhour resources for stretching the project schedules. So I would emphasize the correct timing of consucting the HAZOP in a project schedule as well as tips to reduce the overall effort.

I am interested to present HAZOP related courses. Hazard and Operability Studies are essential towards identifying the inherent risks in a given process design and go further to demonstrate the robustness of a given design. I have a unique and diverse perspective of the HAZOP methodology having participated as a process engineer, process systems engineer and a process safety engineer.

I had the opportunity to lead a HAZOP as the chairman for Takreer refinery Ruwais refinery project. The team of participants included process engineers, operations staff, instrument engineers and other relevant disciples were available on call basis. The HAZOp lasted for two weeks at the end of which a HAZOP report was generated and issued to all parties. A HAZOP register was also created to track the closure of outstanding actions.

Technical Training: the key to a flawless unit operation

Petroleum Refining and allied subjects

Over the years, petroleum refining has transformed from a relatively straight-forward separation of hydrocarbon components based in their boiling points (distillation) to a more complex activity. In recent times, stringent specifications have been set by the regulatory authorities, in-line with HSE concerns, placing restrictions on pollutants like benzene, sulphur and other contaminants. At the same time, with a view to improve performance, characteristics like octane and cetane numbers have been increased in order to provide higher efficiency. The refiners are also encouraged to process higher sulphur crude due to its price advantage on the market. I propose to develop the following courses related to petroleum refining;

Fundamentals of Petroleum refining and key objectives: This course will delve into the basics of petroleum refining, explaining the concept of octane number, cetane number and the overall block flow diagram of a typical refinery. The course will then explain the objective of processes like hydoprocessing, catalytic cracking, catalytic reforming etc.

Petroleum Refining – Meeting the Challenge of Euro-IV specifications head-on: This course will specifically address the challenges imposed by the restriction on Benzene, RVP and reduced sulphur compounds. This course will delve into the additional investments required by refiners and the options they need to evaluate for a revamp scenarios.

Process technologies in Petroleum Refining - Catalytic Reforming and Isomerization: The Catalytic Reforming and Isomerization process units are critical to the smooth operation of the refinery as they have a direct impact on the quality of products like gasoline. This course will explain in detail, starting with the associated chemistry, the block flow diagrams, operating parameters, catalyst requirements etc.

Process technologies in Petroleum Refining - Sulphur recovery and tail gas treating units: The SRU and the TGT units are often referred to as the clean-up units or the dump of the refinery. They are important in terms of the stack emissions of the refinery in order to meet the environmental regulations. This course will explain in detail, starting with the associated chemistry, the block flow diagrams, operating parameters, catalyst requirements etc.

Heat Exchanger Thermal Design / Introduction to boilers

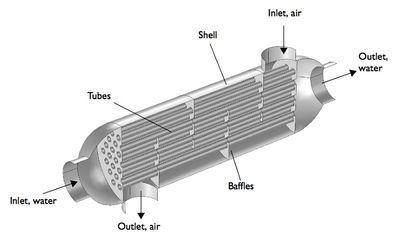

Shell and Tube, Air Coolers, Double Pipe

I have chosen to present a single abstract as the two subjects are closely aligned and share the same chemical engineering fundamentals. Heat transfer has been my technical passion ever since I started studying chemical engineering at the university. At the university, one of my first projects was to evaluate and rate a shell and tube exchanger operating in the ammonia unit. During my career as a process engineer, I have designed (thermal rating) a range of heat exchangers covering different TEMA types, thermosyphon re-boilers, fired heaters, air coolers and other applications.

I then had the opportunity to do a design project on the design of a new and innovative design of a boiler based on combustion of heavy fuels in presence of oxygen. I have also worked extensively on various software’s like HTRI, Proates, HTFS etc for the design of both exchangers and boilers.

With the above level of experience, I feel confident to be able to effectively present the course on heat transfer. Further, I wish to propose the new course on boilers, which essentially will deal with description and analysis of boiler configuration with the help of block flow diagrams, description of various elements of the boiler (combustion chamber, superheater coils, economiser), calculation of boiler efficiency, dew point etc. to optimise the operation of the boiler. The course will also delve into the control and instrumentation aspect while explaining the ratio control for excess air/oxygen.

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Hours

Monday - Friday: 9:30am - 6pm

Saturday: By appointment

Sunday: Closed

Copyright © 2024 USP Future Energies LLP - All Rights Reserved. SILPro is a registered trade-mark.