Process Hazard Reviews

HAZOP

- Hazard analysis and Operability Study is a brainstorming session to identify Process Hazards

SIL with LOPA

SIL with LOPA

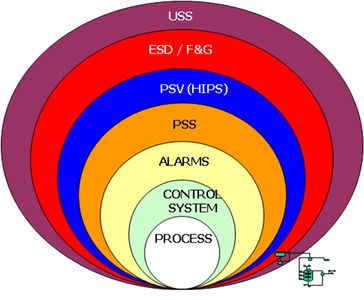

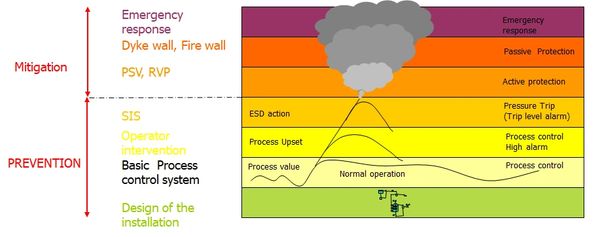

- Layers of Protection Analysis is a brainstorming session to ensure mitigation of high severity and high frequency hazards to ALARP.

Layer of Protection Analysis - "A SIF in time, saves Lives"

SIL with LOPA methodology

- LOPA means layers of protection analysis. The method starts with data developed in the Hazard and Operability study (HAZOP) and accounts for each identified hazard by documenting the initiating cause and the protection layers that prevent or mitigate the hazard. The total amount of risk reduction can then be determined; the need for more risk reduction can be analyzed. If additional risk reduction is required and if it is to be provided in the form of a Safety instrumented Function (SIF), LOPA methodology allows the determination of the appropriate Safety Integrity Level (SIL) for the SIF. The safety lifecycle defined in IEC 61511-1 requires the determination of a safety integrity level for the design of a safety-instrumented function.

Software for HAZOP and LOPA

SILPro® is a proprietary software developed with the objective to carry out integrated HAZOP and LOPA studies. SILPro® is an internet-based application and users can access the software online on payment of a license fee. Licenses are based on the number of simultaneous users. The license fee is payable on a yearly basis and any upgrades to the software would be available on-line.

The seamless and automated transfer of data (consequence to impact event, cause to initiating cause and safeguards to protection layers) from HAZOP to LOPA makes it both efficient and accurate to work with SILPro®

As a tool, the SILPro® software supports the HAZOP and LOPA/SIL Chairman to carry out the study with the software being operated by the scribe. Infact the Chairman and the scribe can simultaneously access the project and record the proceedings.

Our Expertise

- We have a long and validated experience to carry out integrated HAZOP and LOPA studies. The latest trend is to integrate the Hazop and LOPA study to optimize the time and effort required by the participants. The high criticality scenarios are transferred from Hazop to LOPA on-the-go and their safeguards are assessed for adequacy.

Hazard Identification and Risk Assessment

Software tools

Technical Scribing

Software tools

- A good software tool can substantially prune the session time with user friendly features, such as, crosseferencing of hazard scenarios; We use PHAWorks® (Copyright © 1996-2013 Primatech Inc) which has proven to be an indispensable companion over the years.

QRA

Dispersion Modeling

Loss-of-Containment (LOC) of Chlorine Gas from Storage Tank

Disclaimer: This section is taken from ALOHA User’s Manual Feb 2007 for the purpose of information to the user.

What is Dispersion?

Dispersion is a term used by modelers to include advection (moving) and diffusion (spreading). A dispersing vapor cloud will generally move (advect) in a downwind direction and spread (diffuse) in a crosswind and vertical direction (crosswind is the direction perpendicular to the wind). A cloud of gas that is denser or heavier than air (called a heavy gas) can also spread upwind to a small extent.

Dispersion Study

Many different types of air dispersion models exist. They range from simple equations that can be solved by hand to complex models that require massive amounts of input data and powerful computers. The type of model appropriate for a particular use depends on the scale of the problem, the level of detail available for input and required for output, the background of the intended user, and the time available to wait for the model computations to be completed.

There are two separate dispersion models:

Gaussian model. Gaussian model is widely accepted to predict how gases that are about as buoyant as air will disperse in the atmosphere. Such neutrally buoyant gases have about the same density as air. According to this model, wind and atmospheric turbulence are the forces that move the molecules of a released gas through the air, so as an escaped cloud is blown downwind, "turbulent mixing" causes it to spread out in the crosswind and upward directions. As a result, a graph of gas concentration within any crosswind slice of a moving pollutant cloud looks like a bell-shaped curve, high in the center (where concentration is highest) and lower on the sides (where concentration is lower).

Heavy gases. When a gas that is heavier than air is released, it initially behaves very differently from a neutrally buoyant gas. The heavy gas will first "slump," or sink, because it is heavier than the surrounding air. As the gas cloud moves downwind, gravity makes it spread; this can cause some of the vapor to travel upwind of its release point. Farther downwind, as the cloud becomes more diluted and its density approaches that of air, it begins behaving like a neutrally buoyant gas. This takes place when the concentration of heavy gas in the surrounding air drops below about 1 percent (10,000 parts per million). For many small releases, this will occur in the first few yards (meters). For large releases, this may happen much further downwind.

About ALOHA

ALOHA (Areal Locations of Hazardous Atmospheres) is a computer program designed especially for use by people responding to chemical releases, as well as for emergency planning and training. ALOHA models key hazards—toxicity, flammability, thermal radiation (heat), and overpressure (explosion blast force)—related to chemical releases that result in toxic gas dispersions, fires, and/or explosions. ALHOA models three hazard categories:

- toxic gas dispersion

- fires

- explosions.

ALOHA employs several different models, including an air dispersion model that it uses to estimate the movement and dispersion of chemical gas clouds. From this model, ALOHA is able to estimate the toxic gas dispersion, the overpressure values from a vapor cloud explosion, or the flammable areas of a vapor cloud. This can be helpful during an emergency response or planning for such a response

ALOHA can model the dispersion of a cloud of pollutant gas in the atmosphere and display a diagram that shows an overhead view of the regions, or threat zones, in which it predicts that key hazard levels (LOCs) will be exceeded. This diagram is called a threat zone plot. To obtain a threat zone estimate, you must first choose at least one LOC. For toxic gas dispersion scenarios, an LOC is a threshold concentration of the gas at ground level also called Acute Exposure Ground Limits (AEGL)—usually the concentration above which a hazard is believed to exist. For each AEGL, ALOHA estimates a threat zone where the hazard is predicted to exceed that LOC at some time after a release begins. These zones are displayed on a single threat zone plot. ALOHA will display the threat zones in red, orange, and yellow, the red zone represents the worst hazard.

CASE-STUDY - Worksheet

INPUT DATA

SITE DATA:

Location: Central India

Building Air Exchanges Per Hour: 0.36 (sheltered double storied)

Time: March 27, 2018 1609 hours ST (user specified)

CHEMICAL DATA:

Chemical Name: CHLORINE

Molecular Weight: 70.91 g/mol

AEGL-1 (60 min): 0.5 ppm AEGL-2 (60 min): 2 ppm AEGL-3 (60 min): 20 ppm

IDLH: 10 ppm

Ambient Boiling Point: -35.3° C

Vapor Pressure at Ambient Temperature: greater than 1 atm

Ambient Saturation Concentration: 1,000,000 ppm or 100.0%

ATMOSPHERIC DATA: (MANUAL INPUT OF DATA)

Wind: 3 meters/second from E at 5 meters

Ground Roughness: urban or forest Cloud Cover: 5 tenths

Air Temperature: 33° C

Relative Humidity: 50%

SOURCE STRENGTH:

Leak from hole in horizontal cylindrical tank

Non-flammable chemical is escaping from tank

Tank Diameter: 2 meters Tank Length: 6 meters

Tank Volume: 18.8 cubic meters

Tank contains gas only Internal Temperature: 33° C

Chemical Mass in Tank: 281 kilograms

Internal Press: 5 atmospheres

Circular Opening Diameter: 2 inches

Release Duration: 4 minutes

Max Average Sustained Release Rate: 106 kilograms/min (averaged over a minute or more)

Total Amount Released: 218 kilograms

OUTPUT DATA:

THREAT ZONE:

Model Run: Heavy Gas

Red : 945 meters (20 ppm = AEGL-3 [60 min])

Orange : 2.5 kilometers (2 ppm = AEGL-2 [60 min])

Yellow : 4.4 kilometers (0.5 ppm = AEGL-1 [60 min])

Contact Us

EMail:

Postal Address:

D-7 / 7185, Vasant Kunj, New Delhi-110070, India

Landline: +91 11 46032975, Mobile: +91 9650640798

Hours

Monday - Friday: 9:30am-6:00pm

Saturday: By appointment

Sunday: Closed

Copyright © 2024 USP Future Energies LLP - All Rights Reserved. SILPro is a registered trade-mark.